Precision Dentistry, Reliable Dental Lab

Raytops is a manufacturer specializing in providing high-quality dental prosthetics solutions for the global dental industry. We serve dental clinics, laboratories, and import distributors with a comprehensive range of crowns, bridges, dentures, and implant restorations, all crafted to meet the highest standards of precision and reliability. Our products are tailored to support dental professionals in delivering exceptional patient care.

页面: Product

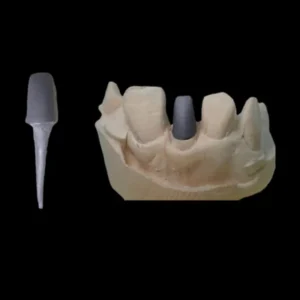

Crown & Bridge

Dental Implants

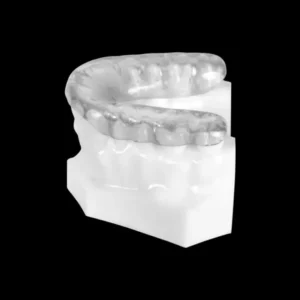

Removable

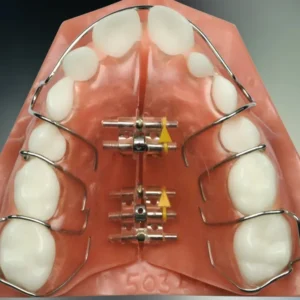

Orthodontics

How to Choose right Dental Lab

Choose a dental lab by what you can measure, not what you’re promised. This guide gives a simple, testable framework to pick a partner that lowers total cost of ownership (TCO) while keeping results predictable across crowns, bridges, and implant work.

Outcomes first: target FPY ≥98%, remake ≤1.5%, on-time ≥98% to cut chairside minutes and rebooks.

Tie quality to cost: model TCO = unit price + (chairside minutes × rate) + remake costs + shipping so price and performance are comparable.

Verify what’s real: ask for quarterly FPY/on-time trends by indication and material (zirconia, e.max, PFM), plus COAs, batch retention, and traceability back to lots and machines.

Digital certainty: confirm a 3Shape/exocad compatibility matrix, encrypted file transfer, and ≤24h end-to-end lookup from order to QC to ship.

Plan the clock: written TAT rules, rush capacity, and monthly SLA reports, not averages.

Remove friction: response SLAs (≤2h/≤24h), structured intake, and pre-design checks that prevent avoidable remakes.

De-risk contracts: clear remake policy, warranty scope, and an RMA → 8D closure path.

Start small: run a 4–8 week pilot, compare TCO, then scale only the lanes that meet thresholds.

As an outsourcing dental lab partner, we work to these standards so your team seats faster with fewer surprises.

Tired of the guessing game? We understand the hidden costs of relying on promises alone. Every single remake, every hour spent chairside adjusting an ill-fitting restoration, and every patient rebooked due to a late case doesn’t just cost money—it costs your reputation and your team’s sanity. That’s why we don’t just talk about price. We built this guide to help you choose a partner based on predictable, measurable performance, allowing you to finally eliminate workflow surprises and reclaim your chairside efficiency.

How to define and find the right dental lab to ensure outcomes and lower total cost (TCO)

Pick a dental lab by the results you can predict and verify: low remakes, fast seating, and on-time delivery. Tie those outcomes to total cost using a few hard metrics—first-pass yield (FPY), remake rate, and chairside minutes—then set clear decision thresholds before you send a case. If a lab cannot share these numbers or meet your thresholds, keep looking.

Define the outcome: fewer remakes, faster seating, predictable schedules

Fewer remakes: judge by FPY on first delivery and by remake rate over a quarter.

Faster seating: look for less chairside adjustment time and fewer shade corrections.

Predictable schedules: confirm on-time rate and cut-off rules for rush vs. standard.

Make these outcomes the basis of selection, not brand claims or single anecdotes.

Link quality to total cost: FPY, remake rate, chairside minutes → TCO

Most doctors focus on the unit price and feel frustrated when that ‘low cost’ crown ends up requiring an hour of adjustment. We believe your time is your most valuable asset. This section links quality metrics directly to the true Total Cost of Ownership (TCO).

| Metric | What it means | How it hits cost |

|---|---|---|

| FPY | Cases seated on first try | High FPY lowers rework, shipping, delay costs |

| Remake rate | % of cases needing redo | Each remake adds lab time + chairside time |

| Chairside minutes | Adjustment minutes per case | Minutes convert directly to provider cost |

| On-time rate | % delivered per promise | Reduces schedule chaos and patient rebookings |

Use these as a simple TCO model: TCO = Lab price + (Chairside minutes × rate) + Remake/Delay costs.

Set a decision threshold: target FPY ≥98%, remake ≤1.5%, on-time ≥98%

Fix thresholds up front (e.g., FPY ≥98%, remakes ≤1.5%, on-time ≥98%).

Ask for last-quarter data and the collection method before a trial.

Run a 4–8 week pilot and compare actuals to thresholds.

Approve, remediate, or exit based on the gap to target and root cause notes.

A lab that reports these metrics consistently—and improves them with you—reduces total cost even when unit prices are similar. As an overseas outsourcing partner, Raytops can align to your thresholds and share quarterly FPY/on-time trend reports without adding workflow burden.

How to verify a dental lab’s quality, materials, and compliance

Verify a dental lab by what you can audit: publishable QC data, materials provenance you can trace, and certifications you can check. Ask for last-quarter FPY, remake rate, and on-time trends broken down by indication (crowns, bridges, implant abutments, veneers) and material (zirconia, e.max/lithium disilicate, PFM, PMMA). Require COAs, batch retention, and IFUs from upstream suppliers. Confirm ISO 13485 and the relevant CE/FDA status, including 510(k) for regulated implant components.

You deserve a lab that is an open book, not a black box. When a patient asks ‘What material is this?’ or ‘Where was this made?’, you need verifiable answers instantly. This section details how we provide certainty, not just promises, about the provenance and quality of every restoration.

Request verifiable QC data: quarterly FPY/on-time trends and methods

Provide FPY, remake rate, and on-time delivery by product family: crowns & bridges, implant bars/abutments, veneers, removable.

Show defect codes by cause: margin mismatch, occlusion high, shade variance, fit at implant platform.

Include measurement system details: scanner/caliper calibration, Gage R&R, sampling frequency, SPC charts.

Disclose rework loop policy: who approves redesign, how chairside minutes are logged, how shipping windows affect TCO.

Share file acceptance stats for digital workflow: STL quality, 3Shape/exocad version matrix, encryption success rate.

Materials provenance & traceability: COA samples, batch retention, IFU

Map each case to material lot: zirconia disk/ingot ID, PFM alloy lot, PMMA puck, resin cartridge.

Request COA samples that match shipped lots; verify dates, composition, shrinkage/sinter profiles.

Confirm batch retention policy (e.g., retain zirconia/ingot remnants and records ≥12 months) and retrievability ≤24h.

Check IFU versions from material brands (e.g., zirconia and e.max) and ensure furnace/cure profiles comply.

Trace end-to-end: order → lot → machine/furnace ID → QC checkpoint → shipping label; require barcode or QR linkage.

Certifications you can check: ISO 13485, CE/FDA, 510(k) if applicable

| Certification / Program | Scope & When It Matters | What to Verify |

|---|---|---|

| ISO 13485 | QMS for medical devices; baseline for labs handling implants | Valid certificate, scope includes CAD/CAM production, expiration dates |

| CE (MDR) | EU market; material/device conformity | Declaration of Conformity, notified body (if applicable), labeling alignment |

| FDA Registration/Listing | US distribution | Facility registration status and product listings up to date |

| 510(k) (implant parts) | Custom abutments/bars where applicable | K-number, indications, milling/workflow within cleared conditions |

| MDSAP (if present) | Multi-market QMS audit | Jurisdictions covered; audit report summary |

| BAA/HIPAA (agreement) | PHI handling for US | Executed BAA, data flow diagram, encryption at rest/in transit |

If a lab can furnish quarterly QC packs, trace materials to lots used in your crowns, bridges, and implant cases, and show live certificates on request, you can trust the workflow—not just the promises. As a global outsourcing dental lab, Raytops provides verifiable FPY/on-time trend packs and COA-linked traceability without adding steps to your team.

Evaluate digital workflow certainty from scan to seat in a dental lab

Judge digital certainty by three verifiable controls: a clear CAD/CAM compatibility matrix, secure file transfer with privacy safeguards, and end-to-end traceability you can query within 24 hours. Ask for proof using real cases across crowns, bridges, implant abutments/bars, veneers, and aligners so you see how the lab handles different indications and materials such as zirconia, e.max, and PFM.

CAD/CAM compatibility & versions: 3Shape/exocad matrix and updates

Supported inputs and versions: 3Shape and exocad release numbers, library versions for major implant systems, and how often the matrix is reviewed.

File integrity: STL/PLY checks, bite scan alignment, and rules for model-less workflows vs printed models.

Library management: validated implant libraries (connections/hex), update procedure, and rollback plan when vendors push changes.

Design rules by indication: minimum thickness for zirconia and e.max, connector sizes for bridges, path of insertion checks for implant bars, and occlusal contact targets.

CAM strategy transparency: rough/finish toolpaths, sinter/mill compensation tables, nesting factors for zirconia disks and PMMA.

Validation evidence: first-article builds per software update, fit photos/videos, and measurement summaries (margin gap, contact points).

Encrypted file transfer & privacy: SFTP/PGP, GDPR, BAA/HIPAA options

Standardize channels: SFTP for bulk case transfer; PGP-encrypted email or HTTPS portal with TLS for exceptions.

Encrypt at rest: server-side encryption for case files, libraries, and COAs linked to crowns, bridges, and implants.

Access control: named user accounts, MFA, least-privilege folders for each clinic/DSO.

Agreements: GDPR DPA for EU entities; BAA/HIPAA for US when PHI is present.

Auditability: immutable logs for uploads, downloads, edits, and design approvals; 12-month log retention minimum.

Incident readiness: breach notification workflow, severity tiers, and response SLAs with a single point of contact.

End-to-end traceability: order → batch → machine → QC → ship (≤24h lookup)

| Stage | Required record | Why it matters | Example field(s) |

|---|---|---|---|

| Order intake | Case ID, indication, shade, due date | Links design to promise date | RT-CASE-24891; crown #16; A2; due Fri |

| Materials | Lot/COA + IFU | Confirms legality and performance | Zirconia disk ZR-08-L210; e.max ingot EM-LT-A2; PFM alloy lot |

| CAD | Software/version, library ID | Reproducible design choices | 3Shape 2023.2; Straumann library v7.1 |

| CAM/Process | Machine/furnace ID, strategy | Root-cause if fit is off | Wieland mill M2-03; sinter curve S-Zr-1450 |

| QC checkpoints | Measured criteria | Quantifies “good” vs remake | Margin gap ≤80 μm; occlusal map screenshot |

| Shipping | Carrier/track, pack time | Meets promised schedule | DHL 2334…; ship 17:30; on-time flag |

Require a live demo: enter a case ID for a zirconia crown or an implant bar and retrieve lot, machine/furnace, QC images, and tracking in one view within 24 hours. Labs that maintain this level of visibility cut chairside minutes and remake risk even as volume scales.

How to evaluate a dental lab’s turnaround time and delivery consistency

Judge turnaround by written rules you can plan against: a clear TAT policy with cut-off times and business-day counting, on-time SLAs with monthly reporting and remedies, and a playbook for peak seasons or disruptions. Ask for evidence across indications—single crowns, multi-unit bridges, implant bars/abutments, veneers, aligners—and materials like zirconia, e.max, and PFM, because complexity changes clock speed.

Standard 4-day TAT and 72-hour rush: define cut-off and business days

Fix the clock start: received-by cut-off (e.g., 14:00 local, valid STL/IO scan, complete Rx, confirmed shade).

Count business days: exclude weekends/holidays for both the lab and destination; publish a calendar for export lanes.

Segment by indication: e.g., zirconia crown 4 business days; 3-unit bridge 5; custom implant abutment 5–6; aligner starter set 5–7.

Define rush lanes: 72-hour for single crowns and PMMA temps; list surcharges, daily capacity caps, and blackout dates.

Bind shipping: state default carrier and service level (e.g., DHL Express 18:00 pickup, DDP or DAP terms).

Confirm rework clocks: remake TAT and whether it preempts standard queues.

On-time delivery SLA & reporting: monthly targets, exceptions, remedies

| Element | Target & Definition | Evidence to Provide | Remedy if Missed |

|---|---|---|---|

| On-time rate | ≥98% delivered by promise date/time | Monthly export by indication/material and lane | Service credit tiered by gap |

| Promise definition | “Ship by” vs “Seat by” (door-to-door) | Policy doc + example cases | Re-quote dates + priority flag |

| Exception codes | Force majeure, customs hold, Rx incomplete | Code list + counts by month | Exclusion policy + proof |

| Predictability | 90th percentile lead time per product | Percentile chart, last 3 months | Capacity add-ons or split lanes |

| Communication | Delay alert ≥1 business day in advance | Timestamps, contact log | Fee waiver for late alert |

Peak-season & contingency plan: capacity buffers, outage/clearance playbooks

Capacity buffers: publish daily max for crowns, bridges, and implant cases; keep a 10–20% reserve for rush and remakes.

Redundancy: dual mills/furnaces, mirrored CAM libraries, and alternate zirconia/PMMA vendors with validated IFUs.

Logistics playbooks: alternate carriers, red/green customs lanes, backup labels, and HS codes per material (zirconia, PFM).

Outage scenarios: power/network failover, manual intake forms, and offline batching so STL to mill never stops.

Transparency: weekly slot forecast during peaks; freeze dates for complex bridges or implant bars; standing update channel.

Labs that codify clocks, publish lane-level reports, and run real contingency drills keep seating predictable and chairside minutes low—even when volume spikes. As an outsourcing dental lab, Raytops operates published cut-offs, 98%+ on-time SLAs, and monthly indication-level reports so clinics can plan crowns, bridges, and implant restorations with fewer surprises.

How dental lab communication and support reduce chairside time

Cut chairside time by standardizing how you and the lab talk, confirm designs, and prevent avoidable remakes. Use hard service targets—first reply ≤2 hours, design confirmation ≤24 hours, issue alerts ≥1 business day before ship—and require playbooks that map to indications (single crowns, multi-unit bridges, implant abutments/bars, veneers, aligners) and materials (zirconia, e.max, PFM).

Response SLAs: first reply ≤2h, design confirmation ≤24h

| Touchpoint | Target | What it prevents | Evidence to request |

|---|---|---|---|

| Case acknowledgment | ≤2h during business hours | Lost files or missed cut-offs | Timestamped intake log |

| Design questions | Batched once daily; final confirmation ≤24h | Iteration lag, shade/occlusion misses | Threaded ticket with decisions |

| Delay alerts | ≥1 business day pre-ship | Last-minute rebooks | Alert log with time stamps |

| Technician access | Named lead + deputy | Context switching, handoffs | Contact card + coverage hours |

Tie SLAs to the indications you run most: e.g., faster lanes for single zirconia crowns and PMMA temps; scheduled checkpoints for implant bars and multi-unit bridges.

Case intake templates & shade guidance: reduce preps/adjustments

Use a single intake form per indication: crown, bridge, implant abutment/bar, veneer, aligner.

Require must-have fields: margin line, material (zirconia, e.max, PFM), stump shade, occlusal scheme, opposing and bite, desired contact tightness.

Attach structured photos: shade under D65 light with reference tab, prep reduction photos with putty index or digital reduction map.

For implants: library/connection brand, scan body lot, tissue depth, path of insertion notes.

Auto-reject incomplete files and send a checklist link so teams fix the gap before the clock starts.

Chairside assistance & pre-design review: prevent avoidable remakes

Pre-design checkpoints: margin clarity score, minimum thickness (e.g., zirconia ≥0.7 mm, e.max ≥1.0 mm on incisals), connector area for bridges, implant clearance around platform.

Virtual try-in: share screenshots of contacts/occlusion maps and emergence profile for implant bars; confirm before CAM.

Shade/texture preview: sample surface texture and translucency choice for anterior zirconia or e.max veneers to cut polishing time chairside.

Post-seat feedback loop: log chairside minutes and micro-adjust reasons (high occlusion, margin rock, proximal tight). Trend by product and doctor to improve FPY.

Labs that codify SLAs, use structured intake, and run pre-design reviews consistently seat faster and remake less across crowns, bridges, implants, and veneers. As a global outsourcing dental lab, Raytops assigns named technicians, runs 2-hour/24-hour service targets, and shares intake checklists so clinics spend fewer minutes adjusting and more time seating.

Dental lab production capacity and supply chain resilience

Capacity is a promise only when it is measured, stress-tested, and protected by redundant supply. Ask your lab to publish daily throughput targets by indication (single crowns, multi-unit bridges, implant abutments/bars, veneers, aligners) and by material stream (zirconia, e.max, PFM, PMMA). Then verify how they scale during peaks, what breaks first, and how fast they recover without pushing remakes or delaying seats.

Daily throughput & elastic capacity: surge handling and load mix

Publish lane capacities: e.g., zirconia crowns 180/day, 3-unit bridges 60/day, custom implant abutments 40/day, PMMA temps 120/day, aligners 200 cases/day.

Show load mix rules: priority for clinical urgency, remake preemption, and caps for rush work.

Prove elasticity: evidence of +20–30% surge for 10 business days without raising remake rate or chairside minutes.

Forecasting rhythm: weekly slot forecast and a 14-day rolling view per lane, shared with clinics/DSOs.

Redundancy & DR: dual site/equipment, power/network failover

Equipment redundancy: paired mills and furnaces per material stream; mirrored CAM servers; nightly image backups.

Library & workflow continuity: version-locked 3Shape/exocad libraries replicated across sites; rollback plans when vendors push breaking updates.

Utilities & network: UPS + generator coverage for critical mills/furnaces; dual ISPs with auto-failover; offline intake forms if portals fail.

Recovery objectives: RTO ≤4h for crown/bridge streams; ≤8h for implant bars; documented drill results from last quarter.

Qualified vendors & safety stock: critical materials lead-time control

| Material/Item | Vendor status | Safety stock policy | What to verify |

|---|---|---|---|

| Zirconia disks/ingots | Dual qualified vendors | ≥6 weeks on hand by shade/thickness | COA matching, sinter profile parity |

| e.max/lithium disilicate | Primary + backup distributor | Reorder triggers tied to 3-week moving avg | IFU versions, furnace validation logs |

| PFM alloys | Approved alloy list with lot tracking | Lot bridging plan during audits | Biocompatibility docs, batch IDs |

| PMMA/resins | Two chemistries validated | Shelf-life rotation, humidity control | Cure profiles, tensile test snapshots |

| Tooling/parts | Redundant toolkits per mill | Preventive maintenance cadence | Downtime reports, spare inventory |

A lab that shows lane-level capacity, drills disaster recovery, and holds qualified material buffers keeps crowns, bridges, and implant cases moving even in peak season. As an outsourcing dental lab, Raytops operates mirrored CAM/milling, dual vendors for zirconia and PMMA, and lane forecasts so your schedules stay predictable without hidden chairside costs.

Dental lab remake policy, warranty, liability, and dispute resolution

Treat policy clarity as risk control. Before onboarding, ask the lab to publish what qualifies for a no-charge remake, the time window, the documentation required, and how warranty and liability caps apply across crowns, bridges, implant abutments/bars, and veneers in materials like zirconia, e.max, and PFM. A transparent policy reduces disputes and protects chairside time.

Remake scope/window/exclusions: cost allocation and logistics

Define eligible causes: margin mismatch, occlusion high, shade variance, wrong library for implant platform; exclude prep changes, new impressions, or shade changes after approval.

Set windows by product: e.g., single zirconia crown 60 days; 3-unit bridge 90; custom implant abutment 120; anterior veneers 60.

Clarify logistics: who pays inbound/outbound freight on no-charge remakes; whether rush fees are waived to protect schedule.

Evidence required: pre-op and try-in photos, bite map, return of original restorations, STL versions, and Rx notes.

Rework vs remake: when a chairside minor adjustment credit applies versus full rebuild.

Warranty & liability caps: coverage, duration, proof requirements

| Topic | Typical coverage | Duration | Proof / Notes |

|---|---|---|---|

| Structural failure (zirconia, PFM frameworks) | No-charge remake if design rules followed | 6–12 months by product | Photos, fracture location, design file, furnace log |

| Esthetics (shade/translucency) | One corrective attempt if intake met | 30–60 days | Shade photo under D65, tab reference, RX match |

| Implant components | Within cleared indications and library | 6–12 months | Library ID, torque notes, platform match |

| Liability cap | Service-credit cap per case/period | Contract term | Caps tied to monthly spend or % of case value |

Dispute workflow: RMA → 8D root-cause → service credit/closure SLA

RMA intake: assign case ID, publish a due date for investigation, and ship labels if parts must return.

8D analysis: define defect, containment, root cause, corrective/preventive actions; include QC photos and CAM/furnace records.

Closure SLA: e.g., 5 business days for crowns/veneers, 7–10 for bridges/implants; issue service credits or schedule a no-charge remake.

Learning loop: tag defect codes and trend monthly by indication and material to drop repeat issues and protect FPY.

When policies are unambiguous—what’s covered, how long, and how closure works—teams spend less time arguing and more time seating. As an outsourcing dental lab, Raytops operates written remake and warranty terms with RMA/8D templates and indication-level trends, so clinics know exactly how crowns, bridges, and implant cases are protected.

Outsourcing dental lab pricing vs. value: modeling transparent costs and predictable TCO

Choose a lab on total cost of ownership, not unit price. Model the full picture: base price plus chairside minutes, remake probability, and shipping windows for crowns, bridges, implant abutments/bars, veneers, and aligners across zirconia, e.max, PFM, and PMMA. A lab that itemizes inclusions, publishes surcharge rules, and hits on-time targets will often deliver a lower TCO even if the sticker price looks similar.

Price structures & inclusions: avoid hidden fees and rework surprises

| Line item | Typical model | Must-include to be fair | Red flags |

|---|---|---|---|

| Base unit price | Per crown/bridge unit; per implant abutment | Design, standard adjustments, QC, basic trays | “Design fee” or “model fee” added later |

| Shade/esthetics | Included for posterior; tiered for anterior veneers | One shade correction included | Per-email or per-screenshot charges |

| Rush | % uplift or flat fee | Published capacity caps; blackout dates | “Case-by-case” quotes only |

| Shipping | Zone + service level | Default service published (e.g., DHL Express) | Surprises on return labels for remakes |

| Remake handling | No-charge within policy | Clear window and evidence list | Ambiguous exclusions that shift blame |

| Digital handling | Portal/SFTP included | Encryption and retention | Fees per STL upload |

TCO calculator: remakes + chairside minutes + shipping windows

Define the formula: TCO = Unit price + (Chairside minutes × hourly rate) + Remake cost × remake probability + Shipping.

Set realistic inputs by indication and material: zirconia crown vs 3-unit bridge vs custom implant abutment; PMMA temps vs e.max anteriors.

Pull last-quarter metrics: FPY, remake rate, on-time rate, average chairside minutes by product.

Price the time: use your true hourly rate (doctor + assistant + room).

Run a 4–8 week pilot; compare Lab A vs Lab B on TCO, not price alone.

Scenario comparison: local vs cross-border; standard vs rush/SLA

| Scenario | What changes | Net effect on TCO |

|---|---|---|

| Local, standard service | Shorter transit; higher unit price | Good for urgent singles; may not scale on cost |

| Cross-border, standard | Lower unit price; export lanes | Best when FPY ≥98% and schedules are stable |

| Cross-border, rush SLA | Rush fees + capacity limits | Use for zirconia crowns/PMMA temps; cap volume |

| Complex implant bars | Longer CAM/CNC windows | Choose lab with proven bar FPY to avoid costly remakes |

If a lab can publish inclusions, show quarterly FPY/on-time by indication, and hold rush capacity without spiking remake rates, your TCO stays predictable as volumes move from single zirconia crowns to multi-unit bridges and implant work. As a global outsourcing dental lab, Raytops provides itemized quotes, TCO side-by-side pilots, and indication-level KPI packs so teams can compare price versus value with no surprises.

Get started with your dental lab partner: trial, quote, or factory tour

Move forward with the shortest, lowest-risk step: start a limited trial, request an itemized quote, or book a live factory tour. Keep it focused on your real case mix—single zirconia crowns, multi-unit bridges, implant abutments/bars, veneers, PMMA temps, and aligners—so the results map to your daily schedule and true TCO.

Start a trial case: SOP, success metrics, no-risk remake policy

Define scope: 10–20 cases across your top indications (e.g., zirconia crowns, 3-unit bridges, custom implant abutments).

Lock metrics and targets: FPY ≥98%, remakes ≤1.5%, on-time ≥98%, chairside minutes benchmark by product.

Establish inputs: standard intake forms, shade protocol, 3Shape/exocad versions, implant library IDs.

Set clocks: cut-offs, rush limits, and remake SLA; confirm who pays shipping on no-charge remakes.

Review cadence: weekly 20-minute stand-up to compare FPY, issues by code (margin, occlusion, shade), and next fixes.

Decide on scale-up: approve lanes that meet targets; remediate or exit others.

Request a detailed quote: by material, indication, and TAT/SLA

Provide matrix pricing for crowns, bridges, veneers, implant bars/abutments, and aligners by material (zirconia, e.max, PFM, PMMA).

Itemize inclusions: design, QC, one shade correction (anterior), encryption/portal, standard trays.

Publish surcharges with caps: rush (72-hour), complex implant frameworks, model printing, international returns.

Bind logistics: default carrier/service (e.g., DHL Express), Incoterms, cut-off time, and customs documents.

Attach KPIs: last-quarter FPY/remake/on-time by indication and material so price maps to outcomes.

Book a 15-minute video tour: verify certificates & workflow live

Certificates: show ISO 13485, CE/FDA status, and any 510(k) for implant components.

Digital workflow: walk through CAD/CAM, nesting for zirconia and PMMA, furnace profiles for e.max, and QC checkpoints.

Security & privacy: SFTP/PGP process, access controls, audit logs, PHI redaction in portals.

Traceability demo: enter a live case ID (e.g., zirconia crown or implant bar) and retrieve lot, machine/furnace, QC images, and tracking in one screen.

Named contacts: meet the lead technician and escalation owner; confirm coverage hours and holiday calendars.

Choosing one of these paths converts “claims” into verifiable data for crowns, bridges, implants, and veneers. As a global outsourcing dental lab, Raytops supports itemized quotes, low-risk trials with clear KPIs, and live tours so teams can commit with confidence.

Conclusion

Choose a dental lab the same way you run a clinic: by measured results and clear rules. When FPY stays high, remakes stay low, and on-time performance holds, chairside minutes drop—and total cost follows. The best partners publish QC data, trace materials, protect files, and keep clocks and capacity honest across crowns, bridges, and implant work. Start with a small trial, compare TCO, and scale only what meets your thresholds. As an outsourcing dental lab, Raytops works to these standards with itemized pricing, KPI packs, and live traceability so your team can seat faster and plan with confidence.